OEM Services: ANTIAN allows clients to customize coding equipment functionality and design, aligning with their brand’s specifications.

Customization Solutions: ANTIAN tailors coding solutions, including content, configuration, and material compatibility, to meet unique production needs.

Logistics Support: ANTIAN ensures quick, secure global delivery of coding equipment and parts to minimize downtime for clients.

VIDEO

Key Features

- Cold Marking Technology: Ensures no heat damage to delicate materials like plastics, glass, and metals.

- High Precision: Delivers clear, sharp, and permanent markings suitable for intricate designs and small surfaces.

- Versatile Application: Ideal for use in electronics, pharmaceuticals, cosmetics, and other high-standard industries.

- Eco-Friendly Operation: No use of consumables like inks, reducing waste and environmental impact.

- High-Speed Performance: Efficiently handles high-volume production lines without compromising quality.

- Durable Coding: Produces wear-resistant and fade-resistant marks for long-term traceability.

- Minimal Maintenance: Low maintenance requirements ensure consistent performance and reduced downtime.

- Seamless Integration: Easily integrates into existing production lines for smooth operation.

- Compliance Ready: Meets strict industry standards for safety, traceability, and product labeling.

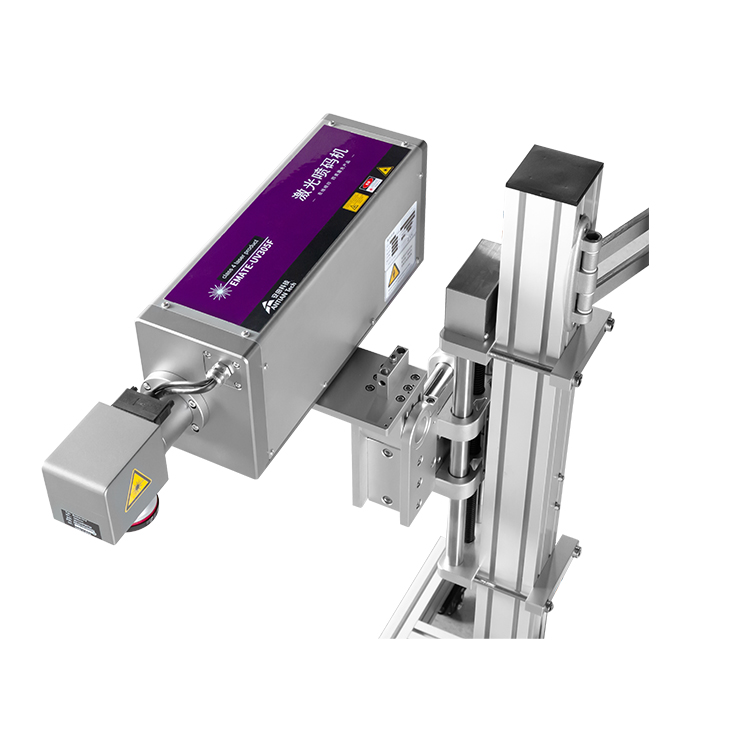

Product Details

Cold Marking Technology

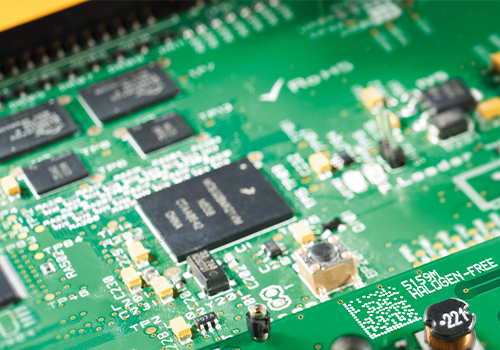

The 10W UV Laser Coding Machine uses advanced cold marking technology, which operates without generating significant heat during the marking process. This ensures no thermal deformation, discoloration, or surface damage to sensitive materials such as plastics, glass, and metals. This feature makes it particularly suitable for marking high-precision components in delicate applications, such as medical devices, electronic circuit boards, and cosmetic packaging. The result is clear, precise, and durable marks that enhance product traceability and brand presentation.

High Marking Quality

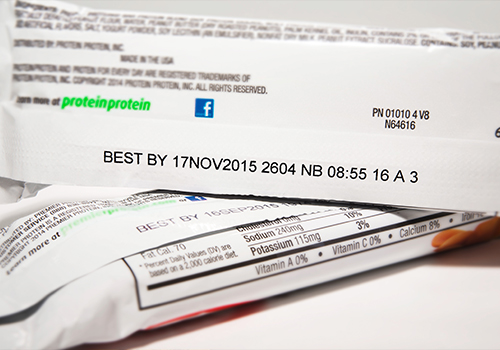

The 10W UV Laser Coding Machine delivers exceptional marking precision and clarity, ensuring high-quality results for even the most intricate designs and challenging applications. Its advanced laser technology produces sharp, detailed, and legible codes that are resistant to fading, abrasion, and environmental factors.

The machine's superior resolution makes it ideal for small character printing and intricate patterns, such as barcodes, QR codes, logos, and serial numbers. This ensures that the marks maintain their integrity throughout the product lifecycle, even under harsh conditions such as exposure to moisture, chemicals, or UV light.

Applications

The 10W UV Laser Coding Machine excels in diverse industries, providing tailored solutions for specific coding challenges:

- Electronics: Marks intricate codes and designs on circuit boards, connectors, and plastic housings without affecting functionality.

- Pharmaceuticals: Ensures compliance with strict regulatory standards by marking batch numbers, expiration dates, and traceability codes on blister packs and glass vials.

- Cosmetics: Creates premium-quality branding, logos, and codes on delicate cosmetic packaging, including bottles, tubes, and jars, enhancing brand value.

- Automotive: Marks durable and precise codes on metal and plastic components, ensuring traceability and compliance with industry standards.

This versatility allows the machine to adapt seamlessly to different production environments, delivering reliable and high-quality results across various materials and applications.

Products Parameter

|

Case materials |

Anodized Aluminum (Laser Head) & Stainless Steel (Control Unit) |

||

|

Laser type |

UV laser source |

||

|

Laser wavelength |

355nm |

||

|

Marking method |

High-precision 2D scanning |

||

|

Marking speed |

≤12000mm/s |

||

|

Main control |

Highly-integrated motherboard with 10-inch touchscreen controller, V5 operation system |

||

|

Cooling method |

Air-cooled |

Water-cooled |

|

|

Operation system |

Linux |

||

|

Type of marking |

Both Dot martix & vector |

||

|

Reflector size |

Standard: 8.5mm |

||

|

Marking filed |

Standard: 110mmX110mm maximum optional:600mmX600mm |

||

|

Positioning method |

Red light positioning, autofocus |

||

|

Number of lines |

No limits within the marking filed |

||

|

Production line speed |

0-300/min(varies according to materials and printing contents) |

189/min(varies according to materials and printing contents) |

|

|

Language |

English, Chinese, Spanish, Russian, Korean, Arabian etc. |

||

|

File format |

BMP/DXF/HPGLIJPEG/PLT |

||

|

Bar code /QR code |

CODE39/CODE128/code126/QRcode/Z-code/DM codeNisual code.etc |

||

|

Power supply |

220V/110V |

||

|

Max Power consumption |

1000W |

||

|

Weight |

41kg((Chinese laser source)) |

39kg(Chinese laser source) |

|

|

Laser head size |

719mmX196mmX155mm |

||

|

Control unit size |

403mmX383mmX160mm |

||

|

Interfaces |

RS-232C/USB2 0/Ethernet.l/O |

||

|

Casing protection level |

IP54(laser head, IP65 is an option ) |

||

|

Working condition |

5 to 40℃; ≤85RH(No-condensing) |

||