OEM Services: ANTIAN allows clients to customize coding equipment functionality and design, aligning with their brand’s specifications.

Customization Solutions: ANTIAN tailors coding solutions, including content, configuration, and material compatibility, to meet unique production needs.

Logistics Support: ANTIAN ensures quick, secure global delivery of coding equipment and parts to minimize downtime for clients.

VIDEO

Key Features

-

Ultra-Fast Marking Speed: Utilizes picosecond laser pulses to achieve exceptionally rapid and efficient marking processes without compromising precision.

-

Cold Processing Technology: Ensures damage-free marking by minimizing heat impact, making it ideal for delicate materials like glass, ceramics, and plastics.

-

High Precision and Clarity: Delivers ultra-fine, detailed markings with exceptional sharpness, suitable for intricate designs, micro-text, and QR codes.

-

Versatile Material Compatibility: Capable of marking a wide range of materials, including metals, coated surfaces, and heat-sensitive materials, across various industries.

-

Eco-Friendly and Low Maintenance: Operates with minimal environmental impact, offering energy-efficient performance and extended laser lifespan for cost-effective long-term use.

Product Details

Applications

-

Electronics Industry:

- High-precision marking on PCBs, microchips, and connectors without damaging delicate electronic components.

- Ideal for traceability codes, serial numbers, and logos.

-

Medical Devices:

- Permanent and legible marking on surgical instruments, implants, and medical packaging to ensure compliance with regulatory standards.

- Maintains biocompatibility and sterility of materials.

-

Luxury Goods and Jewelry:

- Fine engraving and branding on high-end items like watches, gemstones, and metal accessories.

- Achieves intricate designs with superior aesthetic appeal.

-

Glass and Ceramics:

- Precise, damage-free marking on fragile materials for industries such as home décor, automotive components, and drinkware.

- Perfect for creating logos, decorative patterns, and product identification.

-

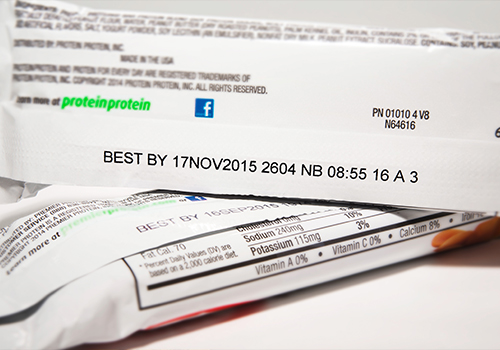

Packaging Industry:

- High-speed coding and marking on plastic and glass containers for beverages, cosmetics, and pharmaceuticals.

- Ensures clear and permanent expiration dates, batch codes, and barcodes.

Products Parameter

UV Picosecond Laser Marking Systems - Technical Specifications

| Parameter | Value |

|---|---|

| Center Wavelength | 355 nm |

| Laser Power | 3W / 5W / 10W |

| Repeat Frequency | 10 kHz – 200 kHz |

| Beam Quality (M²) | ≤1.2 |

| Pulse Width | <10 ps |

| Spot Diameter | ≤20 µm |

| Marking Speed | Up to 7000 mm/s |

| Repeatability | ±0.003 mm |

| Minimum Character | 0.2 mm |

| Minimum Marker Line Width | 0.01 mm |

| Mark Range | 70 × 70 mm to 300 × 300 mm (Optional) |

| Cooling Method | Air-cooled / Water-cooled |

| System Protection Level | IP54 / IP65 (Optional) |

| Operating Environment Requirements | 10°C to 35°C, <90% humidity (non-condensing) |

| Power Requirements | AC 220V ± 10%, 50/60 Hz |

| Overall Power Consumption | ≤1.5 kW |

| Total Weight | ~50 kg |

| Dimensions (L×W×H) | 800 mm × 400 mm × 600 mm |

This specification table highlights the advanced features and high performance of UV Picosecond Laser Marking Systems, catering to a wide range of industrial marking applications.