Small Character Inkjet Printer Working Principle: Comprehensive Guide

Small character inkjet printers, often abbreviated as CIJ (Continuous Inkjet) printers, are widely used for industrial printing, particularly for coding and marking purposes. These printers are essential in various industries for printing date codes, barcodes, lot numbers, and other small characters onto products such as packaging, bottles, plastics, and metals

1. Introduction to Small Character Inkjet Printers

Small character inkjet printers, often abbreviated as CIJ (Continuous Inkjet) printers, are widely used for industrial printing, particularly for coding and marking purposes. These printers are essential in various industries for printing date codes, barcodes, lot numbers, and other small characters onto products such as packaging, bottles, plastics, and metals. Their ability to print high-resolution text and images on a variety of surfaces makes them indispensable in high-speed production lines.

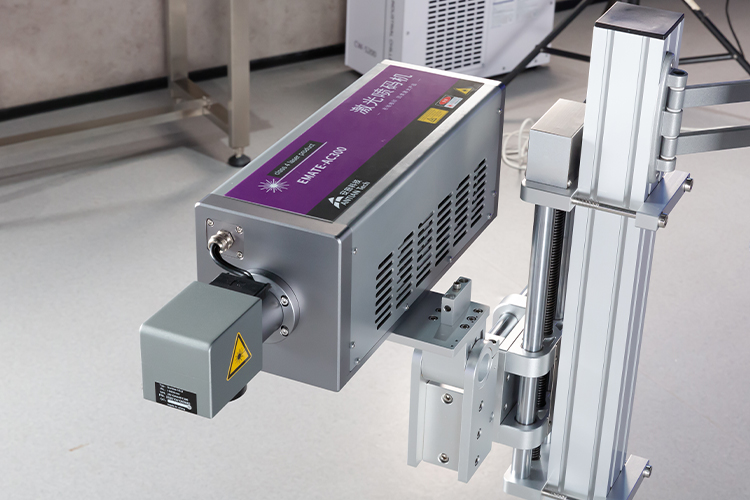

2. Basic Components of a Small Character Inkjet Printer

A typical small character inkjet printer consists of several key components:

- Printhead: Responsible for ejecting ink droplets onto the surface.

- Ink System: Holds and circulates the ink through the printer.

- Controller: Manages the settings and controls the printer's operation.

- Ink Supply & Delivery System: Ensures a consistent supply of ink to the printhead.

3. Working Principle Overview

The working principle of small character inkjet printers can be divided into two primary types of inkjet technology: Continuous Inkjet (CIJ) and Drop-on-Demand (DOD). Each technology follows a different approach to ejecting ink droplets:

- Continuous Inkjet (CIJ): Ink is continuously circulated, and droplets are generated in a steady stream.

- Drop-on-Demand (DOD): Ink is ejected only when needed, either through thermal or piezoelectric methods.

4. Continuous Inkjet (CIJ) Technology

CIJ technology is one of the oldest and most commonly used forms of inkjet printing. In a CIJ printer:

- A high-pressure pump pushes liquid ink through a nozzle, creating a stream of ink droplets.

- An electrically charged plate selectively charges individual droplets.

- These charged droplets are then deflected by an electrostatic field and directed onto the product surface, forming the required characters or symbols.

- Unused droplets are recirculated back into the ink system, allowing for continuous operation.

The main advantage of CIJ technology is its ability to operate at high speeds, making it ideal for fast-moving production lines.

5. Drop-on-Demand Inkjet Technology

In Drop-on-Demand (DOD) systems, ink is only expelled from the printhead when required, reducing ink waste and making the technology more efficient in certain applications. There are two main types of DOD systems:

- Piezoelectric Inkjet Method: Uses a piezoelectric material that deforms when electrically charged, forcing ink out of the nozzle in controlled droplets.

- Thermal Inkjet Method: Heats the ink to create a bubble that forces ink droplets out.

DOD printers are generally used for lower-speed applications that require more precise and high-quality prints, such as product labeling or packaging.

6. Key Differences Between CIJ and DOD

While both CIJ and DOD technologies are used in small character inkjet printers, they differ in several ways:

- Ink Droplet Formation: CIJ creates a continuous stream, while DOD forms droplets as needed.

- Nozzle Operation: CIJ requires continuous operation, whereas DOD only activates the nozzle when printing.

- Printing Speeds: CIJ is suited for high-speed environments, while DOD is slower but offers higher precision.

7. Ink Composition for Small Character Inkjet Printers

The type of ink used in small character inkjet printers depends on the specific application and the printing technology employed:

- Solvent-based inks are common in CIJ printers due to their fast-drying properties on non-porous surfaces like plastics and metals.

- Water-based inks are more common in DOD systems, especially when printing on porous materials such as paper.

- Conductive inks are necessary for CIJ systems to allow for the electrostatic deflection of droplets, while DOD printers can use non-conductive inks.

8. Role of the Printhead in Small Character Printing

The printhead is a critical component that determines the precision and quality of the printing process. Key aspects include:

- Nozzle design and size: Smaller nozzles allow for finer print resolution.

- Droplet ejection: Controlled ejection ensures accurate placement of each droplet.

- Maintenance: Regular cleaning is essential to prevent clogging and ensure consistent print quality.

9. Ink Circulation and Filtration System

CIJ printers have a built-in ink circulation system that recycles unused ink. This system maintains the ink at an optimal viscosity and filters out impurities, ensuring smooth operation over extended periods.

10. Coding and Marking Applications

Small character inkjet printers are widely used for coding and marking in industries like:

- Food and Beverage: Printing expiration dates, batch codes.

- Pharmaceuticals: Lot numbers, regulatory information.

- Packaging: Barcodes, QR codes, logos.

The versatility of small character inkjet printers allows them to print on a variety of materials, including plastic, metal, glass, and even cardboard.

11. How Ink Droplets Are Generated and Controlled

In CIJ systems, ink droplets are controlled by charging each droplet and deflecting it using an electrostatic field. In DOD systems, droplet generation is achieved through either thermal expansion or mechanical deformation of piezoelectric elements, depending on the technology used.

12. Precision and Resolution in Small Character Printing

Both CIJ and DOD technologies offer excellent precision, but DOD is often favored for applications requiring high-resolution prints. By controlling the size and frequency of the ink droplets, small character inkjet printers can achieve resolutions as high as 600 dpi (dots per inch).

13. Maintenance and Troubleshooting of Small Character Inkjet Printers

Proper maintenance is essential to prevent issues like clogged nozzles or ink blockages. Regular cleaning, calibration, and monitoring of ink viscosity can help maintain optimal performance.

- Common issues: Nozzle blockages, ink leakage.

- Solutions: Periodic cleaning, using recommended ink types, and checking the filtration system.

14. Environmental and Safety Considerations

Many inks, especially solvent-based inks, can emit volatile organic compounds (VOCs). Proper ventilation and safety measures, such as wearing protective gear, are important in industrial settings.

15. Future Trends in Small Character Inkjet Printing

Advancements in printhead technology, sustainable ink solutions, and the integration of smart printing systems are shaping the future of small character inkjet printing. Companies are also focusing on automation and reducing environmental impacts by using eco-friendly inks.

FAQs

-

What is a small character inkjet printer?

A small character inkjet printer is a device that prints tiny, high-resolution characters, typically for industrial applications like coding and marking. -

How does continuous inkjet (CIJ) printing work?

CIJ printing works by generating a continuous stream of ink droplets, which are selectively charged and deflected onto the product surface. -

What is the difference between CIJ and DOD printing?

CIJ continuously circulates ink and operates at high speeds, while DOD ejects ink droplets only when needed, offering more precise prints. -

What type of ink is used in small character inkjet printers?

Solvent-based inks are common for CIJ printers, while water-based or oil-based inks are used for DOD printers. -

What industries use small character inkjet printers?

Industries like food and beverage, pharmaceuticals, and packaging rely on these printers for date codes, barcodes, and batch numbers. -

How do I maintain a small character inkjet printer?

Regular cleaning, monitoring ink viscosity, and using recommended inks are key to maintaining performance.