The Ultimate Guide to UV Inkjet Label Printers

In today’s fast-paced world, product packaging and branding have become more crucial than ever. Labels serve not only as identifiers but also as powerful marketing tools that attract consumers, convey critical information, and establish brand identity. The rise of advanced printing technologies, such as the UV inkjet label printer, has revolutionized the labeling industry. Combining high precision, speed, and versatility, these machines have become indispensable for businesses across diverse sectors.

This guide dives deep into the mechanics, advantages, applications, and future potential of UV inkjet label printing machines, offering valuable insights for businesses seeking to elevate their labeling processes.

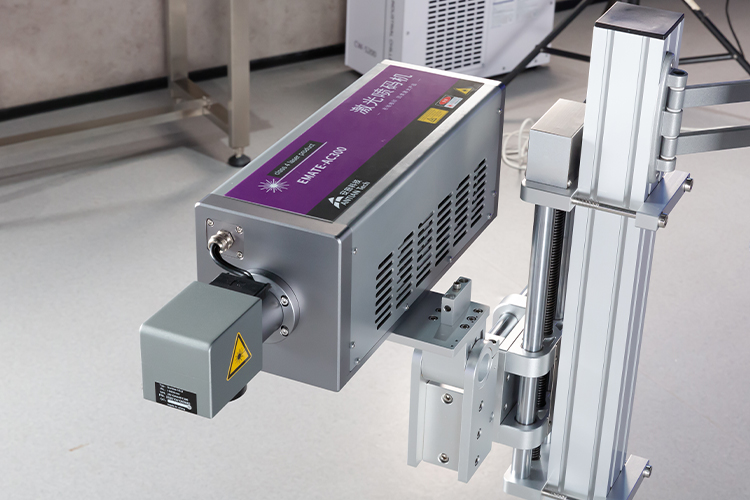

What is a UV Inkjet Label Printer?

A UV inkjet label printer is a cutting-edge device designed to produce high-quality labels using ultraviolet (UV) light to cure ink during the printing process. Unlike traditional printers that require additional drying time, UV inkjet printers ensure instant curing. This results in durable, vibrant labels that stand the test of time.

Key Features of UV Inkjet Label Printers

Instant Drying with UV Curing

UV curing ensures that the ink dries immediately as it is printed, eliminating smudges and reducing production delays.

Wide Substrate Compatibility

These printers can print on various materials, including paper, plastics, glass, metal, and even textiles, providing immense flexibility.

Eco-Friendly Operation

By using minimal solvents and energy-efficient curing methods, UV printers contribute to environmentally sustainable practices.

High-Resolution Printing

With resolutions often exceeding 1200 DPI, UV inkjet printers produce crisp, detailed images and sharp text, suitable for intricate designs.

By leveraging these features, businesses can achieve professional-grade labeling results efficiently.

How UV Inkjet Label Printers Work

The working principle of a UV inkjet label printing machine revolves around precision and advanced curing technology. The process begins with a digital file, such as a logo or label design, being sent to the printer. Using nozzles, the printer sprays tiny droplets of UV-curable ink onto the substrate. As the ink is applied, UV lamps located within the machine emit ultraviolet light, instantly curing the ink.

Step-by-Step Process:

- File Preparation: A digital file is formatted and optimized for printing.

- Ink Application: The printer applies ink in controlled droplets using precise nozzles.

- UV Curing: Ultraviolet light instantly cures the ink, bonding it securely to the substrate.

- Output: The finished label is ready for use without any additional drying or processing.

This innovative process ensures labels are not only vibrant but also resistant to environmental factors such as moisture, UV rays, and abrasions.

Benefits of Using UV Inkjet Label Printing Machines

Investing in a UV inkjet label printer offers a range of benefits that cater to businesses of all sizes. Let’s explore these advantages in detail:

1. Enhanced Print Quality

UV inkjet printers deliver exceptional clarity and color accuracy, ensuring that every label is visually appealing. This makes them ideal for industries where branding and aesthetics are crucial, such as cosmetics and luxury goods.

2. Versatility in Material Compatibility

Unlike traditional printers, UV inkjet machines can handle an extensive range of substrates. Whether you’re printing on flexible plastics, rigid glass, or textured paper, these machines ensure consistent quality.

3. Faster Production Times

The instant curing process eliminates the need for drying time, allowing businesses to produce labels quickly and meet tight deadlines.

4. Durability and Longevity

Labels produced with UV ink are highly resistant to fading, water, and chemicals, making them suitable for harsh environments and long-term use.

5. Cost-Effectiveness

Although the initial investment in a UV inkjet label printing machine may seem significant, the long-term savings on consumables, maintenance, and reduced waste make it a cost-effective choice.

Applications of UV Inkjet Label Printing Machines

UV inkjet printers have revolutionized the way businesses create and apply labels. Here are some key industries where these machines have become indispensable:

1. Food and Beverage Industry

Labels in this industry need to withstand exposure to moisture, refrigeration, and varying temperatures. UV inkjet printers produce durable labels for bottles, cans, and packaging, ensuring they remain intact and visually appealing.

2. Cosmetics and Personal Care

In a market where appearance is everything, high-quality labels play a vital role. UV inkjet printers provide vibrant, detailed designs that enhance product appeal and survive exposure to oils and chemicals.

3. Pharmaceuticals

Pharmaceutical labels require precise text and durable materials to ensure compliance with safety standards. UV inkjet printing delivers accurate results that remain legible over time.

4. Logistics and Shipping

Barcodes, QR codes, and shipping information must remain intact during transit. UV inkjet printers produce labels that are both durable and scannable, ensuring smooth logistics operations.

5. Luxury Goods

High-end products demand premium labeling solutions. UV inkjet printing provides the sophistication and detail needed to reflect the quality of luxury items.

Comparing UV Inkjet Label Printers with Other Printing Technologies

To fully appreciate the value of UV inkjet label printers, it’s helpful to compare them with other common printing methods:

UV Inkjet vs. Flexographic Printing

- Setup Time: Flexographic printing requires creating plates, while UV inkjet is a digital process with minimal setup.

- Cost Efficiency: Flexographic printing is more cost-effective for large production runs, whereas UV inkjet excels in smaller batches.

- Design Flexibility: UV inkjet allows on-the-fly design changes, providing greater flexibility.

UV Inkjet vs. Thermal Transfer Printing

- Print Quality: UV inkjet offers superior image resolution and color vibrancy.

- Durability: UV ink labels are more resistant to environmental factors.

- Speed: While thermal transfer is faster for basic designs, UV inkjet delivers higher-quality results for complex projects.

Factors to Consider When Choosing a UV Inkjet Label Printer

When investing in a UV inkjet label printing machine, it’s crucial to evaluate your specific needs. Here are key factors to consider:

- Production Volume: Choose a printer that matches your business’s production scale.

- Print Resolution: For intricate designs, opt for higher resolution capabilities.

- Material Compatibility: Ensure the printer supports the substrates you commonly use.

- Maintenance: Look for models with easy maintenance and reliable customer support.

- Budget: Balance upfront costs with long-term savings in ink and operational efficiency.

Future Trends in UV Inkjet Label Printing Machines

The future of UV inkjet label printers is bright, with ongoing advancements set to redefine the industry. Key trends include:

1. Increased Automation

Smart printers with AI integration are streamlining workflows, reducing manual intervention, and improving accuracy.

2. Sustainability

Eco-friendly inks and energy-efficient curing technologies are making UV inkjet printing more sustainable, catering to environmentally conscious businesses.

3. Customization

The growing demand for personalized labels is driving innovation in on-demand printing capabilities.

4. Connectivity

Enhanced integration with digital platforms is simplifying the management of print jobs, ensuring seamless operations.

Maintenance Tips for UV Inkjet Label Printers

Proper maintenance ensures your UV inkjet label printing machine operates efficiently. Follow these tips:

- Regular Cleaning: Prevent nozzle clogs by cleaning the print heads frequently.

- Use Genuine Consumables: Always use manufacturer-recommended inks and parts.

- Monitor UV Lamps: Replace UV lamps as needed to maintain optimal curing performance.

- Software Updates: Keep the printer’s firmware up to date for improved functionality.

- Proper Storage: Store substrates in controlled environments to avoid warping or damage.

Conclusion

The UV inkjet label printer is a transformative tool that empowers businesses to create high-quality, durable, and visually appealing labels. With its versatility, efficiency, and eco-friendly attributes, this technology meets the diverse needs of industries ranging from food and beverages to luxury goods. By investing in a UV inkjet label printing machine, businesses can enhance their branding, streamline operations, and stay ahead in an increasingly competitive market.

As technology continues to advance, the role of UV inkjet printing in the labeling industry will only grow, offering endless possibilities for innovation and creativity.