Understanding the Different Types of Ink Used in Small Character Inkjet Printers

Explore the various types of ink used in small character inkjet printers, including solvent-based, water-based, and UV-curable inks, and their applications across industries.

Introduction

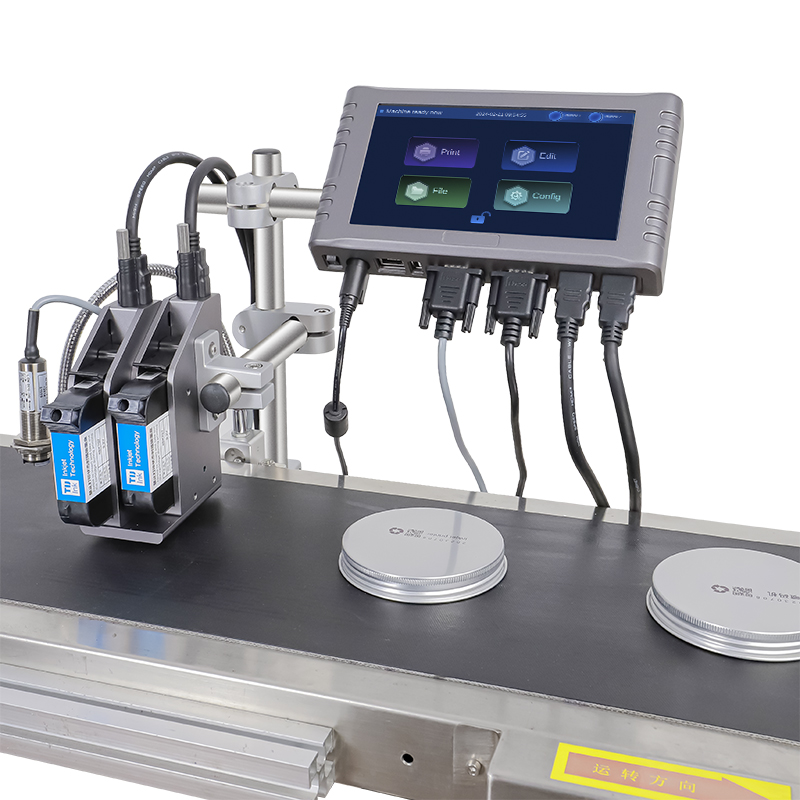

Small character inkjet printers are essential for printing high-resolution text, barcodes, expiration dates, and other important information on a wide range of materials. To ensure optimal performance and print quality, choosing the right type of ink is crucial. The ink used in these printers must be compatible with the materials being printed on, withstand the environmental conditions, and meet the specific needs of different industries, such as food and beverage, pharmaceuticals, and electronics.

In this article, we’ll dive into the different types of ink commonly used in small character inkjet printers, their properties, and how they are applied in various industrial sectors.

1. Solvent-Based Inks

Solvent-based inks are one of the most commonly used types of ink in small character inkjet printers, particularly in Continuous Inkjet (CIJ) systems. These inks consist of solvents that dissolve pigments or dyes, allowing the ink to adhere effectively to non-porous surfaces like plastic, glass, metal, and films. The fast-drying nature of solvent-based inks makes them ideal for high-speed production environments.

-

Key Characteristics:

- Fast drying, even on non-porous surfaces.

- Excellent adhesion to a wide variety of materials.

- Resistant to moisture, chemicals, and abrasion.

-

Applications:

Solvent-based inks are widely used in industries where durability is critical, such as the food and beverage, pharmaceutical, and automotive sectors. These inks are particularly effective for printing on plastic bottles, glass containers, aluminum cans, and packaging films. -

Advantages:

- Quick drying time, ideal for high-speed production lines.

- Suitable for printing on difficult substrates.

- Long-lasting prints that resist fading and wear.

2. Water-Based Inks

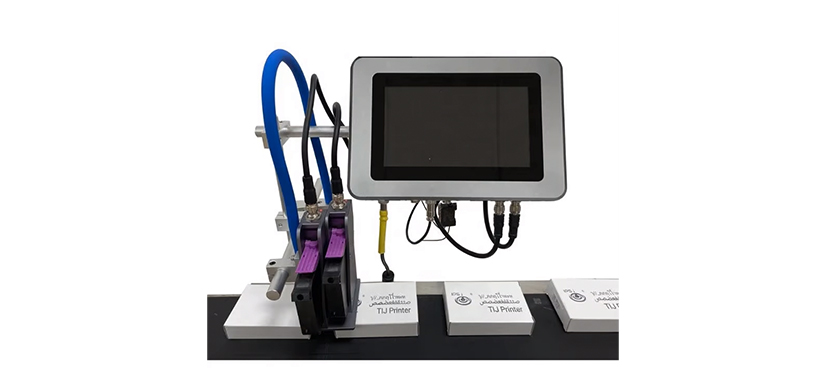

Water-based inks are often used in Drop-on-Demand (DOD) inkjet printers and are favored for applications that require more environmentally friendly printing solutions. These inks use water as the main solvent, making them safer for the environment and reducing the emission of volatile organic compounds (VOCs). However, water-based inks are best suited for printing on porous surfaces like paper and cardboard, as they may not adhere well to non-porous materials.

-

Key Characteristics:

- Non-toxic and eco-friendly.

- Slower drying time compared to solvent-based inks.

- Best for porous surfaces.

-

Applications:

Water-based inks are commonly used for printing on cardboard packaging, paper labels, and other absorbent materials. They are often seen in industries like publishing, packaging, and textiles where environmental concerns are important, and the substrate allows for proper ink absorption. -

Advantages:

- Reduced environmental impact.

- Non-toxic and safe for use in industries with strict health regulations.

- High-quality printing on porous materials.

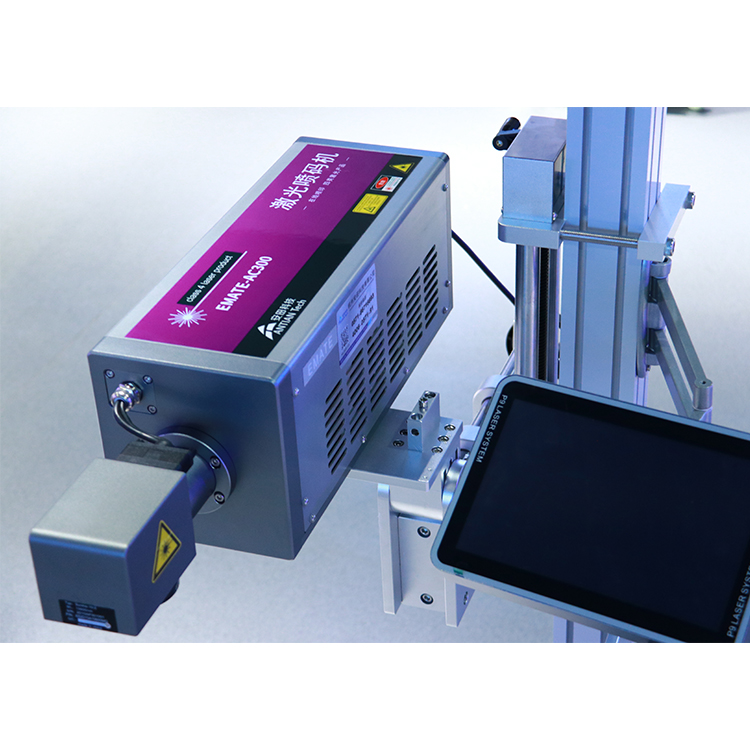

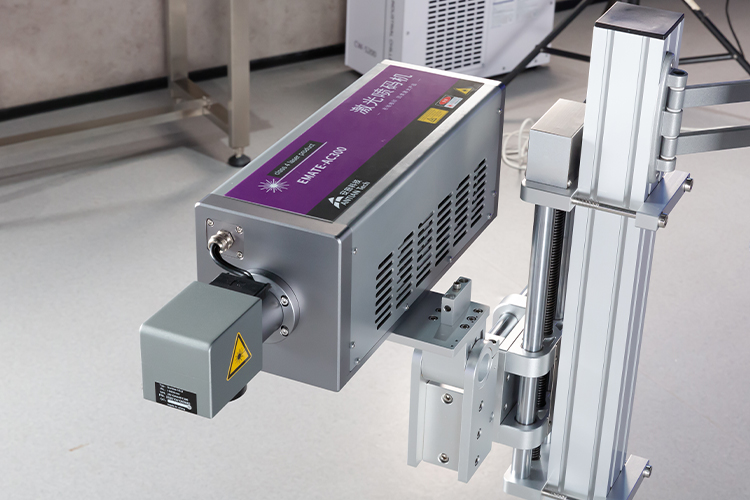

3. UV-Curable Inks

UV-curable inks are a modern solution used in small character inkjet printers that require instant curing. These inks contain photo-initiators that react when exposed to ultraviolet (UV) light, immediately hardening the ink upon exposure. This technology provides excellent adhesion to both porous and non-porous materials, offering high durability and print quality.

-

Key Characteristics:

- Instant curing when exposed to UV light.

- High resistance to smudging, scratching, and environmental factors.

- Suitable for a wide range of surfaces.

-

Applications:

UV-curable inks are ideal for printing on plastics, metals, glass, and coated papers. They are widely used in electronics, medical devices, and industrial packaging where precision and durability are paramount. This type of ink is particularly useful in industries that require rapid production with minimal downtime for drying. -

Advantages:

- Instant drying eliminates smudging and bleeding.

- Superior adhesion to a variety of materials.

- High-quality, durable prints that resist fading and scratching.

4. Alcohol-Based Inks

Alcohol-based inks are a type of solvent ink but use alcohol as the primary solvent. These inks dry quickly, similar to solvent-based inks, but offer improved adhesion on specific materials like rubber, flexible plastics, and certain metals. Alcohol-based inks are popular in environments where quick drying and strong adhesion are essential, especially for products that may be exposed to harsh conditions during transportation or use.

-

Key Characteristics:

- Fast-drying.

- Good adhesion to flexible materials.

- Resistant to smudging and chemical exposure.

-

Applications:

Alcohol-based inks are commonly used for printing on rubber tires, electrical components, and automotive parts. They are also effective for marking cables and wires, where flexibility is a key requirement. -

Advantages:

- Quick drying time.

- Good adhesion to flexible and challenging surfaces.

- Durable prints suitable for industrial use.

5. Oil-Based Inks

Oil-based inks are typically used in Drop-on-Demand printers, offering excellent print clarity on porous materials. These inks are similar to water-based inks but use oil as a carrier, which allows for slower drying times and deeper penetration into absorbent substrates. Oil-based inks provide long-lasting prints and are often used in applications where print permanence is important.

-

Key Characteristics:

- Deep penetration into porous materials.

- Long-lasting and fade-resistant.

- Slower drying time compared to other ink types.

-

Applications:

Oil-based inks are primarily used for printing on paper, cardboard, textiles, and other porous materials. They are common in industries like publishing, packaging, and advertising, where print longevity and clarity are important. -

Advantages:

- Highly durable and fade-resistant prints.

- Ideal for long-term applications.

- Rich color quality and clarity.

6. Specialty Inks (Conductive and Fluorescent Inks)

For specific applications, specialty inks such as conductive inks and fluorescent inks are used in small character inkjet printers.

-

Conductive Inks: Used in electronics for printing circuits or markings that require electrical conductivity, these inks are crucial for industries like PCB manufacturing.

-

Fluorescent Inks: These inks are used for printing codes that are invisible under normal light but become visible under UV light, making them perfect for security coding, anti-counterfeiting, and quality control purposes.

-

Applications:

Conductive inks are used in electronics manufacturing for printing circuit paths on printed circuit boards (PCBs), while fluorescent inks are used in pharmaceutical and high-security packaging industries. -

Advantages:

- Specialty functions for unique applications.

- Fluorescent inks provide added security.

- Conductive inks offer precision in electronic component production.

Conclusion

Choosing the right type of ink for small character inkjet printers depends on various factors, including the substrate, environmental conditions, and industry-specific requirements. Whether it’s the fast-drying solvent-based inks for high-speed production lines, eco-friendly water-based inks for sustainable packaging, or UV-curable inks for precise, durable printing on challenging materials, each type of ink plays a crucial role in ensuring high-quality prints that meet industry standards.

As industries continue to evolve and demand more sustainable and innovative solutions, inkjet technology, and the inks they use, will advance to meet these needs. By selecting the right ink, businesses can ensure reliable and high-quality prints for their specific applications.

FAQs

-

What is the most commonly used ink in small character inkjet printers?

Solvent-based inks are the most commonly used due to their fast drying times and strong adhesion to non-porous surfaces. -

Can water-based inks be used on plastic or metal surfaces?

Water-based inks are best suited for porous surfaces like paper and cardboard. For non-porous materials like plastic or metal, solvent-based or UV-curable inks are recommended. -

What are UV-curable inks used for?

UV-curable inks are used for printing on both porous and non-porous materials and are ideal for applications requiring quick drying and high durability. -

Why are solvent-based inks preferred in high-speed production lines?

Solvent-based inks dry quickly, even on non-porous surfaces, making them ideal for high-speed production environments where efficiency is key. -

What industries use conductive inks?

Conductive inks are commonly used in the electronics industry, particularly for printing circuits on printed circuit boards (PCBs).